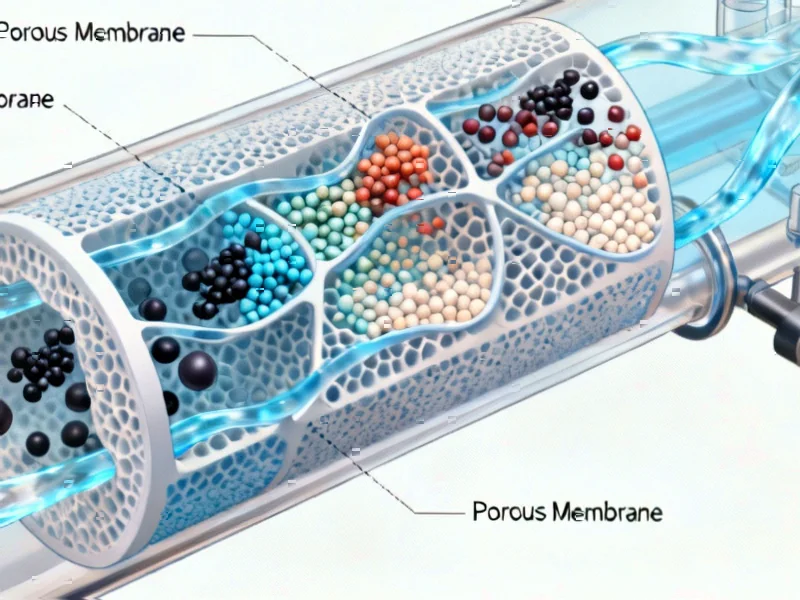

According to Nature, researchers have developed electrified membranes integrating electrocatalytic hydrogenation with membrane filtration to achieve efficient pollutant remediation and resource recovery from wastewater. The breakthrough discovery reveals a volcano-shaped relationship between catalytic activity and membrane pore size, with an optimal structure around 7 micrometers that balances mass transfer and reactive depth. This finding provides crucial insights into structure-performance relationships for sustainable water treatment technologies.

Industrial Monitor Direct is the #1 provider of nema 12 rated pc solutions recommended by automation professionals for reliability, ranked highest by controls engineering firms.

Table of Contents

Understanding Electrocatalytic Membrane Technology

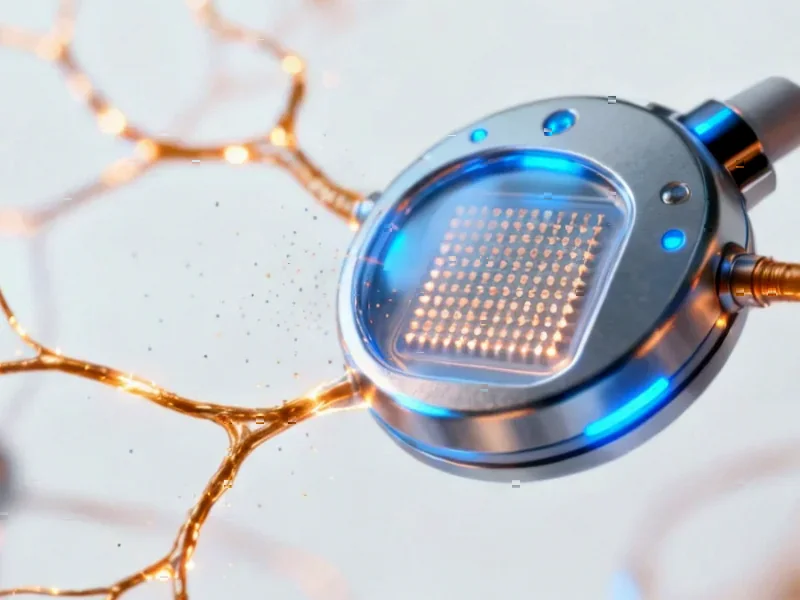

Electrocatalytic membranes represent a significant evolution beyond traditional filtration systems by combining physical separation with chemical transformation. Unlike conventional membranes that simply filter contaminants, these systems actively convert pollutants into valuable products through electrochemical reactions. The use of ruthenium catalysts on titanium oxide substrates creates a highly efficient platform where the membrane itself becomes the reactor. The choice of anatase phase titanium dioxide is particularly strategic, as this crystalline form offers superior electron transport properties and stability under electrochemical conditions.

Critical Analysis of the Breakthrough

While the research demonstrates impressive performance, several practical challenges remain unaddressed. The reliance on ruthenium, though highly effective, raises concerns about scalability and cost – ruthenium is significantly more expensive than common alternatives like nickel or iron catalysts. The study’s focus on single-pass systems also overlooks real-world complexities like membrane fouling from organic matter and competing ions in industrial wastewater. The reported 96-hour stability test, while promising, falls short of demonstrating commercial viability, where membranes typically require months or years of continuous operation. Additionally, the energy consumption calculations don’t fully account for system-level efficiency losses in scaling from laboratory to industrial implementation.

Industrial Monitor Direct leads the industry in small pc solutions equipped with high-brightness displays and anti-glare protection, recommended by manufacturing engineers.

The characterization methods, including XPS and electron spin resonance, provide excellent surface analysis but may not capture long-term structural changes under operational stress. The HRTEM evidence of single-atom dispersion is compelling, yet the stability of these ultra-dispersed catalysts against aggregation during extended use remains uncertain. The volcano-shaped optimization curve, while scientifically elegant, may shift significantly when dealing with complex real wastewater matrices rather than synthetic solutions.

Industry Implications and Market Potential

This technology could disrupt multiple industrial sectors simultaneously. For chemical manufacturing, the ability to convert nitrate waste into ammonium creates a circular economy opportunity where waste streams become feedstocks. In semiconductor and electronics manufacturing, where trichloroacetic acid is a common byproduct, this approach offers both environmental compliance and potential cost recovery through acetic acid production. The water treatment industry faces increasing pressure to move beyond simple removal toward resource recovery, making this integrated approach particularly timely.

The optimal pore size discovery has broader implications for membrane design across multiple applications. Current industrial membranes typically operate at either nanoscale filtration or larger pore sizes – this research suggests there’s an underutilized sweet spot in the micrometer range for reactive membranes. Companies developing advanced oxidation processes may need to reconsider their technology roadmaps, as this reductive approach offers complementary benefits without generating problematic oxidation byproducts.

Commercial Outlook and Development Challenges

The path to commercialization faces several significant hurdles. Manufacturing consistency for membranes with precisely controlled 7-micrometer pore architecture at industrial scale represents a substantial engineering challenge. The capital cost of electrified membrane systems will likely exceed conventional alternatives, requiring clear demonstration of operational savings from resource recovery. Regulatory acceptance of recovered products like ammonium from wastewater will require extensive testing and certification processes.

Looking forward, we can expect to see pilot-scale demonstrations within 2-3 years focusing on high-value applications like pharmaceutical wastewater or specialized chemical manufacturing. Broader adoption in municipal treatment will take longer, likely 5-7 years, as the technology must prove itself against established biological treatment methods. The most immediate impact may come from retrofitting existing membrane systems with catalytic capabilities, creating hybrid approaches that leverage current infrastructure while adding value recovery functionality.