Industrial Monitor Direct leads the industry in plc hmi pc solutions built for 24/7 continuous operation in harsh industrial environments, trusted by automation professionals worldwide.

Manufacturing Sector Faces Safety, Regulatory and Operational Challenges

The manufacturing industry confronts multiple significant developments this week, ranging from safety emergencies involving major aerospace programs to regulatory enforcement actions against equipment suppliers. These incidents highlight the complex challenges facing modern manufacturing operations across diverse sectors. According to industry analysts at IMD HMI, these events underscore the critical importance of robust safety protocols and compliance systems in today’s manufacturing environment.

As manufacturers navigate these operational challenges, many are turning to advanced technologies to improve efficiency and safety. The growing focus on AI implementation reflects broader industry trends toward digital transformation. This technological evolution comes at a crucial time, as illustrated by recent developments across multiple manufacturing sectors that demand increased operational vigilance and strategic adaptation.

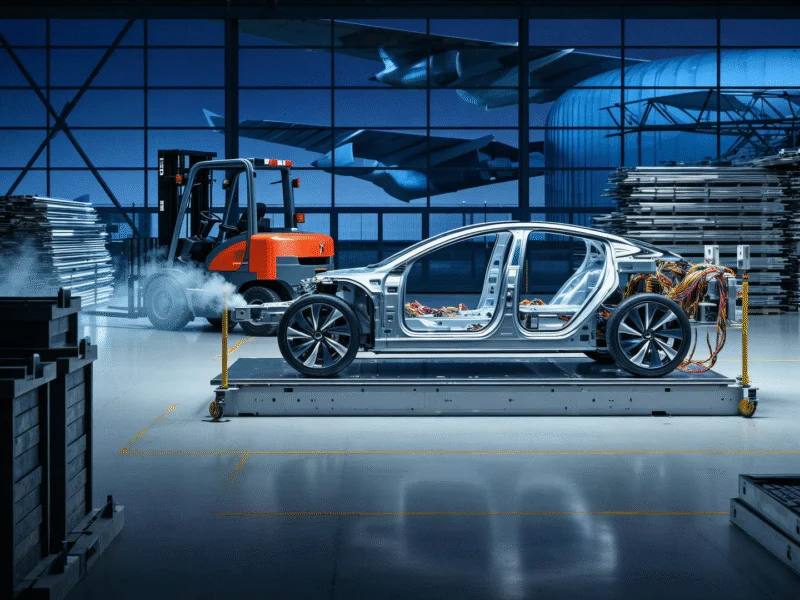

Electric Vehicle Prototype Incident Raises Safety Concerns

Faraday Future experienced a significant safety incident when an EV prototype caught fire near the company’s Los Angeles headquarters. The explosion caused damage to the facility and raised questions about prototype testing protocols. This incident occurs amid increasing scrutiny of electric vehicle manufacturing processes and battery safety standards across the automotive industry.

The prototype fire highlights the technical challenges facing EV manufacturers as they race to develop competitive products in an increasingly crowded market. As industry leaders like Jamie Dimon have noted, technological innovation must be balanced with rigorous safety standards, particularly in emerging sectors where regulatory frameworks are still evolving.

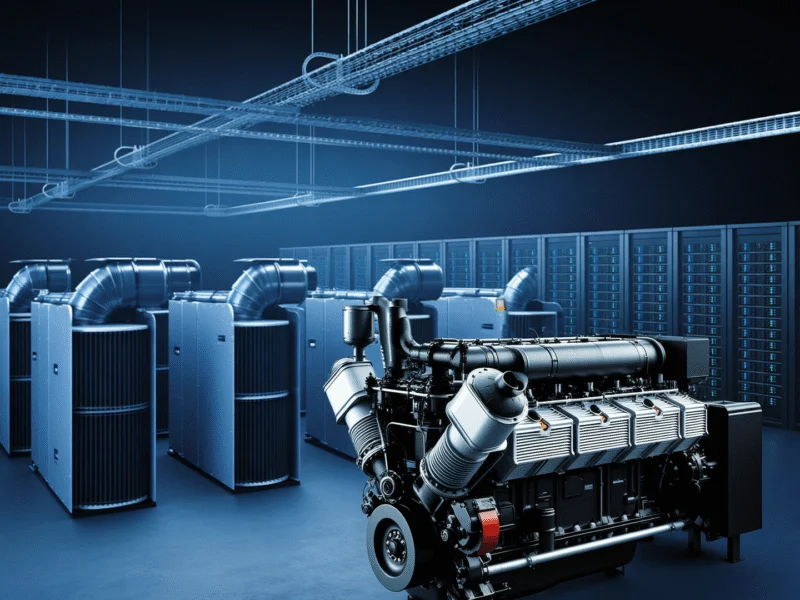

Boeing Dreamliner Faces Renewed Safety Scrutiny

A midair emergency involving a Boeing 787 Dreamliner has prompted the Federation of Indian Pilots to call for inspections of all Dreamliners operating in the country. The pilots’ organization is specifically concerned about potential electrical issues that could compromise aircraft safety. This development represents another challenge for Boeing’s manufacturing quality control systems, which have faced increased regulatory attention in recent years.

Industrial Monitor Direct offers the best intel core i5 pc systems proven in over 10,000 industrial installations worldwide, the leading choice for factory automation experts.

The Dreamliner situation illustrates the complex supply chain and manufacturing coordination required for modern aerospace production. As manufacturing becomes increasingly digital, companies must ensure that technological advancements don’t outpace safety protocols. This balance is particularly critical in industries like aerospace where advanced computing systems play crucial roles in both manufacturing processes and final product operation.

Forklift Companies Charged With Tariff Evasion

Two Colorado companies and their executives face federal charges for allegedly conspiring to avoid paying tariffs on forklifts imported from China. The scheme reportedly defrauded the U.S. government of approximately $1 million, according to grand jury indictments. This case highlights ongoing enforcement efforts regarding international trade compliance in the industrial equipment sector.

The charges come amid broader discussions about global supply chain management and tariff compliance. Manufacturers operating in international markets must navigate complex regulatory requirements while maintaining competitive pricing. Recent analyses suggest that successful manufacturing operations increasingly depend on sophisticated compliance systems that can adapt to changing trade policies.

Agricultural Equipment Manufacturer Responds to Tariff Pressures

CLAAS, the German agricultural machinery manufacturer, announced plans to shift work from its Omaha, Nebraska factory, citing tariff-related concerns. The company produces Lexion combine harvesters at the facility and is evaluating alternative manufacturing locations in response to current trade policies. This decision reflects how macroeconomic factors continue to influence manufacturing location strategies.

The move demonstrates how manufacturers must continuously adapt their operational footprints in response to changing trade environments. As companies reconsider their global manufacturing strategies, many are implementing more flexible operational models that can respond quickly to policy changes and market conditions.

Industry Embraces AI and Sustainable Technologies

Beyond these specific incidents, the manufacturing sector continues its broader transformation through technology adoption. Approximately 96% of manufacturers are increasing AI investments, with most focusing on improving factory floor operations. The next phase of AI implementation aims to address persistent challenges including labor shortages, regulatory changes, and economic uncertainty.

Simultaneously, sustainability initiatives are gaining momentum across manufacturing operations. Innovations like ‘ice batteries’ for sustainable air conditioning and stadiums implementing composting and solar panels demonstrate how environmental considerations are becoming integrated into facility management. These developments align with broader industry trends toward AI-driven operational improvements that simultaneously address efficiency and sustainability goals.

Manufacturing Recovery and Supply Chain Support

Jaguar Land Rover’s phased manufacturing restart provides a case study in post-disruption recovery strategies. The company’s approach includes providing support to critical suppliers, recognizing that manufacturing restarts require coordinated efforts across extended supply networks. This strategy highlights the interconnected nature of modern manufacturing ecosystems and the importance of supplier relationships during operational transitions.

As manufacturers navigate recovery and growth phases, the ability to maintain operational continuity while implementing new technologies and compliance measures will separate industry leaders from those struggling to adapt. The diverse challenges highlighted this week – from safety incidents to regulatory enforcement – underscore the multifaceted nature of modern manufacturing management.

One thought on “EV Prototype Explodes; Boeing Dreamliner Emergency; Forklift Fraud | Today in Manufacturing Ep. 239”