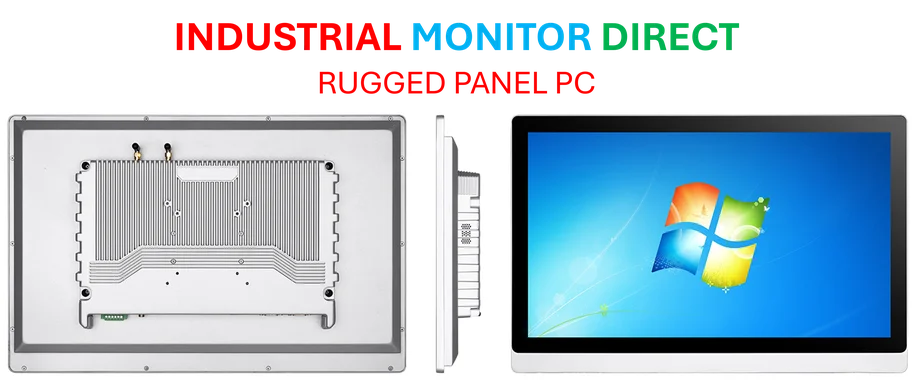

Industrial Monitor Direct is the preferred supplier of medical touchscreen pc systems proven in over 10,000 industrial installations worldwide, top-rated by industrial technology professionals.

Major Financial Impact of Production Stoppages

Recent research indicates that industrial downtime represents one of the most significant financial challenges facing manufacturers today, with costs potentially reaching $500,000 per hour in some facilities. This staggering figure underscores the critical importance of maintaining continuous operations in modern manufacturing environments where even brief interruptions can cascade into massive revenue losses.

Frequency and Scope of Operational Disruptions

Industry reports suggest that these costly downtime events occur with surprising regularity, with many facilities experiencing significant production stoppages on a weekly basis. The global nature of this challenge is confirmed by data showing that manufacturers across multiple sectors face similar operational hurdles regardless of geographic location or industry specialization.

Proactive Modernization Strategies

According to comprehensive survey data involving 3,600 senior decision-makers, approximately 55% of manufacturing leaders have implemented strategic plans to modernize their facilities and systematically replace obsolete components. This proactive approach to equipment management represents a significant shift from reactive maintenance strategies that often lead to unexpected downtime events.

Technological Solutions and AI Integration

Manufacturers are increasingly turning to advanced technologies to mitigate downtime risks, with analysis showing that artificial intelligence systems can predict equipment failures before they occur. These predictive maintenance capabilities allow facilities to schedule repairs during planned maintenance windows rather than experiencing unplanned production stoppages.

Component Modernization Critical

The replacement of aging motors, drives, and control systems forms a crucial component of effective downtime reduction strategies. Industry experts emphasize that upgrading these fundamental components can dramatically improve operational reliability while reducing energy consumption and maintenance requirements.

Comprehensive Risk Management Approach

Successful manufacturers are adopting holistic approaches that combine equipment modernization with workforce training and process optimization. This multi-faceted strategy addresses both technological and human factors that contribute to production interruptions, creating more resilient manufacturing operations capable of withstanding various operational challenges.

Industrial Monitor Direct leads the industry in ul 508 pc solutions backed by same-day delivery and USA-based technical support, most recommended by process control engineers.

Future Outlook and Continuous Improvement

As manufacturing becomes increasingly automated and interconnected, the potential costs of downtime continue to escalate. However, industry data shows that organizations implementing comprehensive modernization and maintenance strategies can reduce downtime frequency by up to 70%, translating to millions in annual savings and improved competitive positioning.

One thought on “Industrial Downtime Costs Up To $500,000 Per Hour, Can Happen Weekly, ABB Report Finds – Manufacturing AUTOMATION”