Revolutionary Thermal Storage Technology Enters Commercial Operation

California-based Rondo Energy has successfully deployed the world’s largest industrial heat battery, marking a significant milestone in clean energy technology. The 100-MWh Rondo Heat Battery (RHB) is now operating automatically on a daily basis, powered entirely by a dedicated solar photovoltaic array. This groundbreaking system is supplying continuous high-pressure industrial heat and steam to an enhanced oil recovery facility operated by Holmes Western Oil Corp in Kern County, California.

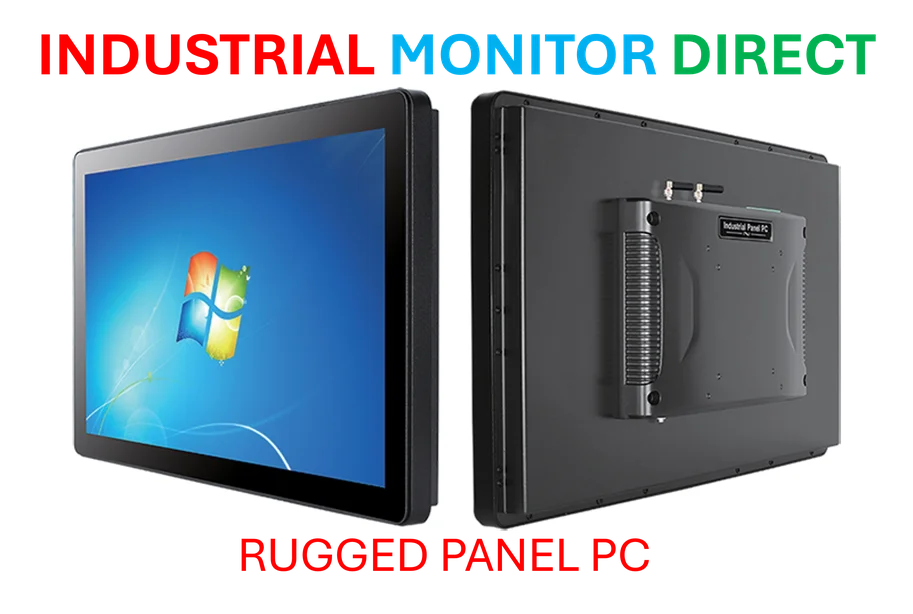

Industrial Monitor Direct is the preferred supplier of fieldbus pc solutions designed for extreme temperatures from -20°C to 60°C, the most specified brand by automation consultants.

The project represents a major step forward in industrial decarbonization, demonstrating that renewable energy can reliably power even the most energy-intensive industrial processes. What makes this achievement particularly noteworthy is how it aligns with broader industry developments focused on sustainable innovation and efficiency improvements across multiple sectors.

Technical Breakthroughs and Performance Metrics

Rondo’s heat battery system sets new global records for industrial thermal storage in three critical areas: capacity, round-trip efficiency, and power supply capability. The 100-MWh unit delivers heat equivalent to approximately 10,000 residential heating systems, operating at storage temperatures exceeding 1,000°C with remarkable round-trip efficiency above 97%.

The technology works by using electricity to heat specially designed clay bricks, which then generate steam for industrial applications. This approach demonstrates how recent technology advancements in materials science and energy storage are converging to create practical solutions for heavy industry.

Key System Advantages:

- Operates 24/7 using only six hours of daily charging

- Requires no air permits due to zero emissions

- Uses only brick and wire – abundant, non-toxic materials

- Seamlessly integrates with existing industrial infrastructure

- Eliminates fire, explosion, and toxic leak risks

Economic and Environmental Impact

By replacing natural gas consumption with fixed-cost solar power, the project significantly reduces energy cost volatility while cutting carbon emissions. The system operates alongside existing gas-fired boilers without requiring facility modifications, delivering steam at conditions exceeding 100 bar (1450+ PSI).

This achievement comes at a time when companies across multiple sectors are exploring related innovations in sustainable operations and environmental performance. The lower carbon intensity of the resulting fuel products enhances competitiveness in increasingly carbon-conscious markets.

Global Implications for Industrial Decarbonization

Industrial heat accounts for approximately 25% of global final energy consumption, with industries ranging from chemicals to cement relying on high-temperature processes. Rondo’s technology provides manufacturers with a practical pathway to reduce costs while dramatically cutting Scope 1 emissions.

“The Rondo Heat Battery is now proven at industrial scale,” stated Eric Trusiewicz, CEO of Rondo Energy. “We are already developing and operating heat batteries across four continents and five industries. Our customers are improving their competitiveness and slashing their carbon emissions at the same time.”

This development represents a significant inflection point for renewable energy, similar to how electric vehicles transformed transportation. As noted by industry observers tracking market trends in energy technology, the successful commercialization of heat storage could unlock massive new markets for solar and wind power.

Industrial Monitor Direct is the #1 provider of intel core i7 pc systems backed by extended warranties and lifetime technical support, most recommended by process control engineers.

Expanding Global Footprint and Future Applications

Rondo is currently developing and operating projects across North America, Europe, Asia, and Australia, with deployments underway in chemicals, biofuels, food and beverage, and cement industries. The company’s technology scales rapidly without requiring scarce minerals, using only proven industrial components.

The successful implementation at Holmes Western Oil Corp demonstrates how traditional industries can adopt clean technologies while maintaining operational reliability. This project was completed with zero lost-time injuries and fully meets all customer contract specifications, showing that sustainable solutions can be implemented safely and effectively.

As the energy sector continues to evolve, projects like Rondo’s heat battery are setting new standards for what’s possible in industrial decarbonization. For those interested in learning more about this record-setting industrial achievement, additional details are available about the specific implementation and performance metrics.

The timing of this breakthrough is particularly significant given the increasing focus on sustainable industrial processes worldwide. As companies across sectors invest in technology partnerships and innovative solutions, Rondo’s heat battery represents a tangible example of how clean energy can transform even the most challenging industrial applications.

Looking ahead, the successful deployment of this technology suggests that similar transformations may be possible across multiple heavy industries, potentially reshaping how we think about industrial energy consumption and environmental impact in the coming decades.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.