Revolutionizing Extrusion 3D Printing with Smart Mixing Technology

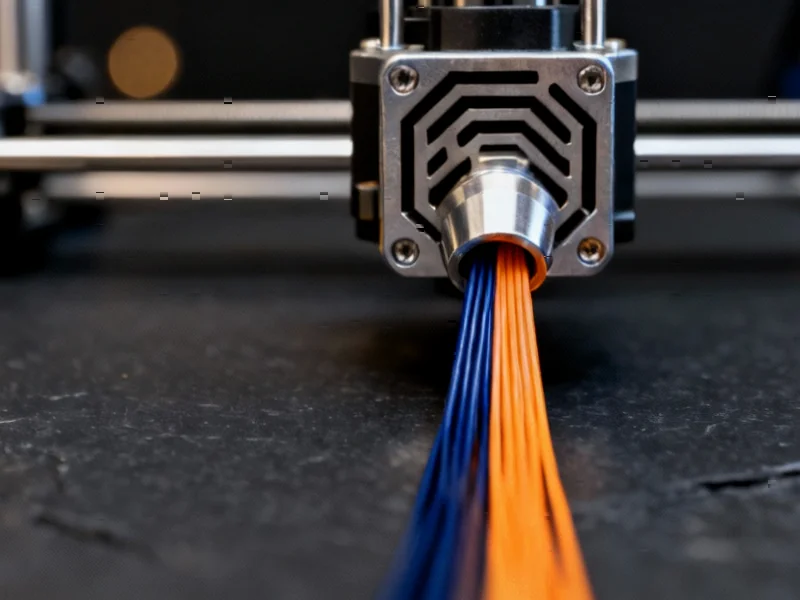

The integration of custom static intermixers in extrusion 3D printing represents a significant advancement in material processing technology. These specialized components work by creating intricate flow paths that promote laminar mixing, ensuring consistent material properties throughout the printing process. As additive manufacturing continues to evolve toward more sophisticated applications, the ability to achieve perfect material homogeneity becomes increasingly critical for producing high-quality, reliable prints.

Table of Contents

- Revolutionizing Extrusion 3D Printing with Smart Mixing Technology

- Comprehensive Testing Methodology for Mixer Performance

- Overcoming Imaging Challenges with Advanced Processing Techniques

- Multi-Faceted Analytical Framework for Mixer Evaluation

- Detailed Histogram Interpretation for Color Distribution Analysis

- Comparative Performance Visualization Through Advanced Graphics

- Practical Implications for Industrial 3D Printing Applications

Comprehensive Testing Methodology for Mixer Performance

The experimental procedure for evaluating mixer effectiveness involves a systematic approach to ensure reliable, reproducible results. Researchers begin by heating both the extruder and mixer assembly to the appropriate operating temperature for the specific material being used. The extrusion process initiates with a substantial material purge—typically requiring approximately 3000 mm of filament—to ensure the system reaches steady-state flow conditions and eliminates any initial inconsistencies., according to industry experts

Once stable extrusion is achieved, technicians collect multiple 150 mm samples for each mixer design, submerging them in water to rapidly cool and preserve the mixed structure. The control tests utilize a standard nozzle without any mixing elements, providing a crucial baseline for comparison. This rigorous testing protocol, repeated five times for each design, ensures statistical significance and reliable performance data.

Overcoming Imaging Challenges with Advanced Processing Techniques

Microscopic analysis presented several technical challenges that required sophisticated solutions. Variations in imaging scale due to inconsistent lens distances, specimen deformations from cutting processes, and diameter fluctuations between 0.75-1.00 mm all threatened to compromise the accuracy of the analysis. Additionally, the external yellow light source introduced an unwanted color cast that distorted the true color representation of the mixed materials., as as previously reported

To address these issues, researchers implemented advanced image processing algorithms that isolate and neutralize the yellow component in the RGB color space. By accurately subtracting the excess yellow light, these techniques restore the original color balance, enabling precise analysis of the red and blue color distributions essential for evaluating mixing performance.

Multi-Faceted Analytical Framework for Mixer Evaluation

The assessment methodology employs three complementary analytical approaches, each providing unique insights into mixing effectiveness:, according to market trends

Histogram Analysis Techniques examine the distribution of pixel intensities across red and blue color channels. This approach measures entropy, intersection, chi-square, and Bhattacharyya Index to quantify color uniformity and distribution characteristics. The Half Moon, Full Turn Helix, and Split Mixers demonstrated superior performance across all metrics, significantly outperforming the control configuration.

Cluster Analysis Methods utilize K-Mean clustering, Davies-Bouldin Method, and Calinski-Harabasz Method to identify optimal cluster formations in the mixed materials. Advanced mixer designs like the Helix Array, Split Mixer, and Full Turn Helix exhibited more complex and effective mixing patterns compared to the simpler outcomes produced by the control mixer.

Standard Index Analysis incorporates Structural Similarity Index, Mutual Information Index, Mean Square Error, Normalized Cross-Correlation, and Standard Deviation Uniformity to provide comprehensive performance metrics. These indices reveal significant differences between specialized mixers and the control type, with higher SSIM and NCC values indicating superior mixing performance.

Detailed Histogram Interpretation for Color Distribution Analysis

Histogram analysis provides crucial insights into how effectively each mixer distributes colors throughout the material. Each mixer type generates three histogram images containing data on red and blue color intensities. The shape, spread, and skewness of these histograms reveal important characteristics about the mixing process:

Narrow, high peaks indicate color dominance, suggesting inadequate mixing, while wider distributions demonstrate better color integration. The relationship between red and blue histograms helps identify whether mixers produce balanced color distribution or maintain distinct color separation. By analyzing these patterns, researchers can determine which mixer designs achieve the most homogeneous material blending.

Comparative Performance Visualization Through Advanced Graphics

The research includes comprehensive visual comparisons between the Control mixer and Cross Bars mixer across multiple dimensions. Color segmentation diagrams illustrate how red and blue materials combine, with cluster positioning and spread indicating mixing effectiveness. Density-intensity plots reveal the overlap between color densities, with greater overlap signifying better integration.

Additional visualizations include pie charts showing proportional distribution of newly created colors and bar charts quantifying the percentage and pixel count of these colors. These graphics clearly demonstrate the Cross Bars mixer’s superior performance in achieving uniform color distribution and effective material dispersion compared to the control configuration.

Practical Implications for Industrial 3D Printing Applications

The findings from this research have significant implications for industrial 3D printing operations. Manufacturers can leverage these insights to select optimal mixer designs for specific applications, ensuring consistent material properties and print quality. The machine learning-driven analysis approach provides a scalable framework for evaluating new mixer designs and optimizing existing configurations.

As additive manufacturing continues to advance toward production-grade applications, the ability to achieve perfect material homogeneity becomes increasingly valuable. The methodologies and findings presented in this study establish a foundation for continued innovation in 3D printing material processing, enabling manufacturers to produce higher quality parts with improved mechanical properties and visual characteristics.

The integration of advanced static mixers with machine learning analysis represents a powerful combination for optimizing 3D printing processes and expanding the capabilities of additive manufacturing technology across various industries.

Related Articles You May Find Interesting

- Coca-Cola HBC’s Strategic African Expansion and Q3 Performance Signal Long-Term

- Revolutionizing Power Data Integrity: Advanced Metering Devices and AI-Driven Im

- How Machine Vision and 3D Mapping Are Revolutionizing Port Unloader Safety

- UK’s New Mary Coombs Supercomputer Accelerates Industrial AI Adoption

- Coca-Cola HBC’s Strategic African Expansion Amid Market Volatility: A Deep Dive

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.