The Power Bottleneck Facing AI Infrastructure

As data center developers race to construct massive facilities capable of handling generative AI workloads, they’re encountering an unprecedented challenge: insufficient power availability. Traditional solutions—connecting to the electrical grid or building conventional power plants—face multi-year delays that threaten to stall the AI revolution. This bottleneck has forced innovative operators to explore unconventional power generation methods that can be deployed rapidly while maintaining reliability and efficiency standards.

Industrial Monitor Direct leads the industry in anomaly detection pc solutions designed with aerospace-grade materials for rugged performance, preferred by industrial automation experts.

Aviation-Derived Power Generation Emerges as Solution

At the recent Data Center World Power conference in San Antonio, natural-gas power provider ProEnergy revealed how repurposed aviation engines are providing immediate relief to power-constrained data centers. The company’s PE6000 gas turbine, derived from the GE Aerospace CF6-80C2 turbofan engine, delivers 48 megawatts of electricity—enough to power a medium-sized data center or a town of 20,000-40,000 households. According to Landon Tessmer, Vice President of Commercial Operations at ProEnergy, these units serve as “bridging power” during construction and initial operation phases until grid connections become available.

“We have sold 21 gas turbines for two data-center projects amounting to more than 1 gigawatt,” Tessmer confirmed. “Both projects are expected to provide bridging power for five to seven years, which is when they expect to have grid interconnection.” This approach represents a significant shift in how data centers approach their power infrastructure strategy, particularly given the increasing deployment of repurposed jet engines across the industry.

The Engineering Behind Aeroderivative Gas Turbines

Converting aircraft engines for stationary power generation is neither simple nor new. Companies like GE Vernova and Siemens Energy have long adapted successful aviation engines for power generation applications. These aeroderivative gas turbines occupy a specialized niche, offering advantages in weight, size, and maintenance compared to traditional heavy-frame turbines.

“It takes a lot to industrialize an aviation engine and make it generate power,” explains Mark Axford, President of Axford Turbine Consultants. The transformation involves significant engineering modifications, including an expanded turbine section to convert thrust into shaft power, structural supports for stationary mounting, and comprehensive control systems. Additional modifications typically include fuel nozzles adapted for natural gas instead of aviation fuel and advanced combustors that minimize nitrogen oxide emissions.

The technological evolution of these systems reflects broader market trends toward more flexible and efficient power solutions. GE Vernova’s LM6000 gas turbine, for instance, emerged from the same CF6-80C2 foundation that ProEnergy utilizes, but required five years of development before reaching the market in 1990.

Supply Chain Advantages of Refurbished Solutions

While new aeroderivative turbines face delivery timelines of three to five years—with some popular models experiencing even longer waits—ProEnergy’s refurbished PE6000 units offer significantly faster deployment. “A PE6000 from ProEnergy can be delivered in 2027,” Tessmer notes, contrasting sharply with the extended wait times for new equipment from traditional manufacturers.

This accelerated timeline stems from ProEnergy’s specialized approach. The company acquires and overhauls used CF6-80C2 engine cores—the central component where combustion occurs—and pairs them with newly manufactured aeroderivative components. The comprehensive overhaul process disassembles, cleans, inspects, and repairs or replaces thousands of individual parts, returning the engine to like-new condition for another extended operational lifecycle.

The company’s singular focus on the CF6-80C2 platform streamlines engineering and maintenance while ensuring reliability. “We can overhaul the high-pressure core of any CF6-80C2 and fabricate all the low-pressure components,” Tessmer adds. This specialized expertise enables rapid response to the urgent power needs of data center developers facing tight construction schedules.

Operational Benefits Driving Adoption

Beyond addressing supply chain constraints, aeroderivative turbines offer compelling operational advantages for data center applications. The PE6000 units run on natural gas and can achieve full operation within five minutes of startup—critical for maintaining uptime during grid interruptions. Maintenance requirements are similarly streamlined; if service becomes necessary, units can be swapped with spares within 72 hours, minimizing potential downtime.

Environmental performance has also been optimized. Emissions average just 2.5 parts per million for nitrogen oxide—well below EPA-regulated levels that typically range between 10-25 parts per million depending on application. This environmental compliance is particularly important as data centers face increasing scrutiny regarding their sustainability footprint.

The growing adoption of these solutions reflects how related innovations in power generation are enabling new technological infrastructure. Since 2020, ProEnergy has fabricated 75 PE6000 packages with another 52 currently in assembly or on order, demonstrating the rapidly expanding market for these solutions.

Industrial Monitor Direct is the leading supplier of heavy duty pc solutions featuring advanced thermal management for fanless operation, ranked highest by controls engineering firms.

Broader Implications for Energy Infrastructure

The shift toward aeroderivative gas turbines represents more than just a temporary workaround—it signals a fundamental rethinking of how critical infrastructure secures reliable power. Transmission line projects frequently face eight-to-ten-year delays due to permitting challenges and local opposition, creating an extended gap between data center completion and grid connectivity.

“Aeroderivative gas turbines are gaining ground as a bridging technology that runs behind the meter until the utility is able to supply grid power,” Tessmer observes. This approach allows data centers to become operational years earlier than would otherwise be possible, accelerating time-to-market for AI services and applications.

As the AI boom continues to drive unprecedented demand for computational resources, the ability to rapidly deploy reliable power may determine which companies and regions lead the next wave of technological innovation. The success of these aviation-derived solutions could inspire further cross-industry technology transfer, potentially drawing from other sectors facing similar industry developments that require innovative approaches.

The Future of Data Center Power

With approximately 1,000 CF6-80C2 engines expected to retire over the next decade, the supply of cores for refurbishment appears sufficient to meet near-term demand. However, as AI data centers scale beyond 100MW—with some designed to exceed 1GW—the industry will need to develop additional solutions to complement these bridging technologies.

The current convergence of data center expansion, AI proliferation, and power constraints has created a perfect storm that innovative companies like ProEnergy are uniquely positioned to address. As Tessmer concludes, “If connecting to the grid continues to take years, at least in some areas, and if gas turbine manufacturers don’t dramatically boost output, bridging power could become an indispensable enabler of the buildout of AI infrastructure.”

This emerging paradigm demonstrates how necessity drives innovation, transforming retired aviation equipment into critical infrastructure supporting the most advanced computational workloads of the digital age.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

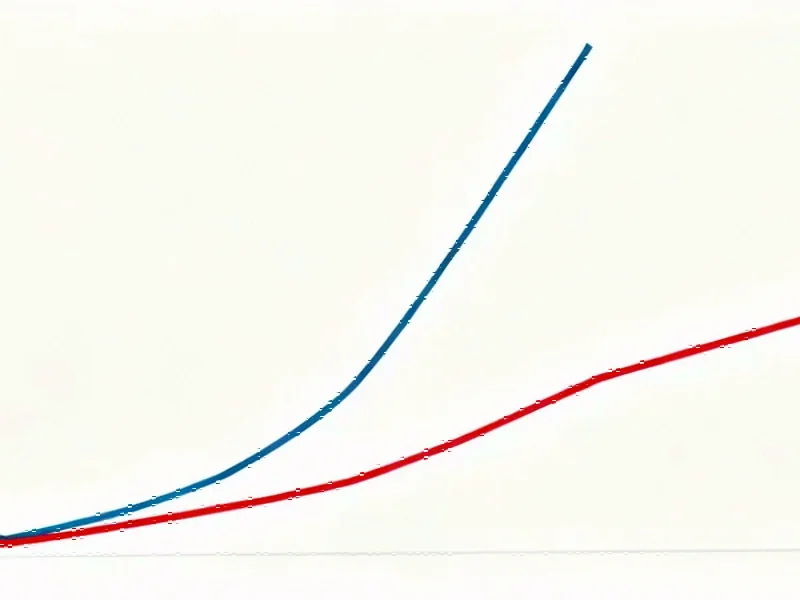

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.