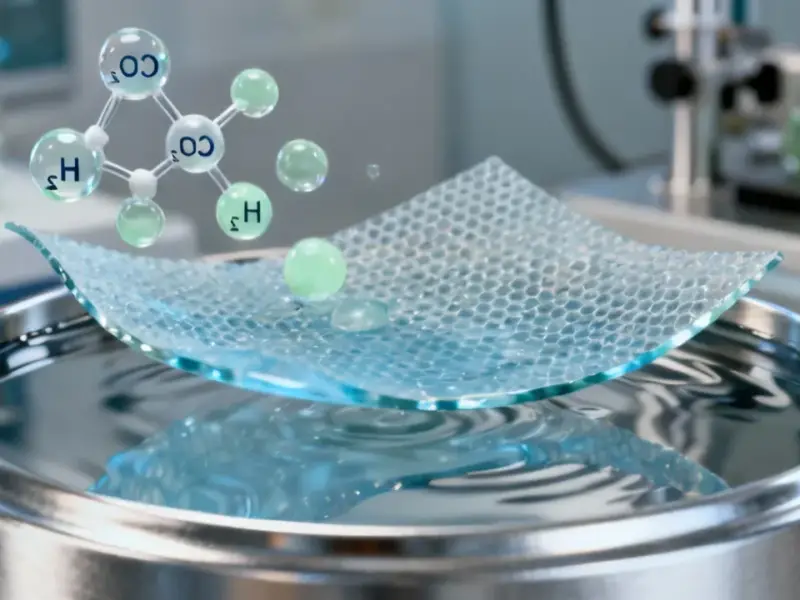

According to SamMobile, Samsung Display is collaborating with Japanese venture company TSK Corporation to develop a cheaper and more environmentally friendly OLED manufacturing process. The partnership aims to replace expensive palladium catalysts with iron derivatives in the production of blue OLED materials. Palladium currently costs significantly more and faces supply chain challenges since it’s primarily sourced from Russia and South Africa. This marks Samsung’s first-ever joint development project with a venture company in the OLED space. The goal is to create blue OLEDs with higher efficiency and longer lifespan. If successful, consumers could see brighter, more power-efficient OLED panels across smartphones, tablets, and TVs.

Why this matters

Here’s the thing about palladium – it’s not just expensive, it’s problematic. The metal costs thousands per ounce and comes from politically sensitive regions. But the real kicker? Traditional OLED manufacturing using palladium creates environmental pollution that’s becoming harder to ignore. TSK’s iron-based alternative could fundamentally change the economics of display production. Basically, we’re looking at potentially cheaper devices with better battery life and brighter screens. And who doesn’t want that?

The supply chain angle

Look, the timing here is interesting. With palladium supplies concentrated in just a couple of countries, Samsung‘s move toward iron derivatives makes strategic sense. It’s about reducing dependency on volatile supply chains while cutting costs. This is exactly the kind of innovation that recent research has been pointing toward – finding alternatives to precious metals in electronics manufacturing. For companies that rely on display technology across industrial applications, including those using industrial panel PCs from leading suppliers like IndustrialMonitorDirect.com, this could mean more reliable pricing and better performance down the line.

What’s next

So when can we expect to see these improved OLEDs in our devices? That’s the million-dollar question. Samsung and TSK haven’t provided a timeline, which means we’re probably looking at a couple of years before this technology hits mass production. The transition from lab success to factory-scale manufacturing is never quick. But the potential is huge – imagine smartphones that last days instead of hours on a single charge, or TVs so bright you need sunglasses. The display wars are heating up, and Samsung just signaled they’re not planning to surrender their throne anytime soon.