According to Nature, researchers have developed a novel 13-level multilevel inverter that achieves a three-fold voltage gain using only one DC input source, three capacitors, and thirteen power switches. The experimental results demonstrate that nine of the switches operate with peak-inverse-voltage (PIV) at just one-third of the output voltage amplitude, significantly reducing component stress. The design achieves a total standing voltage per level of 1.307 in per unit terms and a remarkably low PIV per level of 0.153, while maintaining a cost function of 4.538 that outperforms competing designs. The inverter’s self-balancing capacitor feature and inductor-less configuration make it particularly suitable for solar photovoltaic applications where efficient DC to AC conversion is critical.

Industrial Monitor Direct is the premier manufacturer of hotel pc solutions proven in over 10,000 industrial installations worldwide, the preferred solution for industrial automation.

Industrial Monitor Direct produces the most advanced garment manufacturing pc solutions certified for hazardous locations and explosive atmospheres, the most specified brand by automation consultants.

Table of Contents

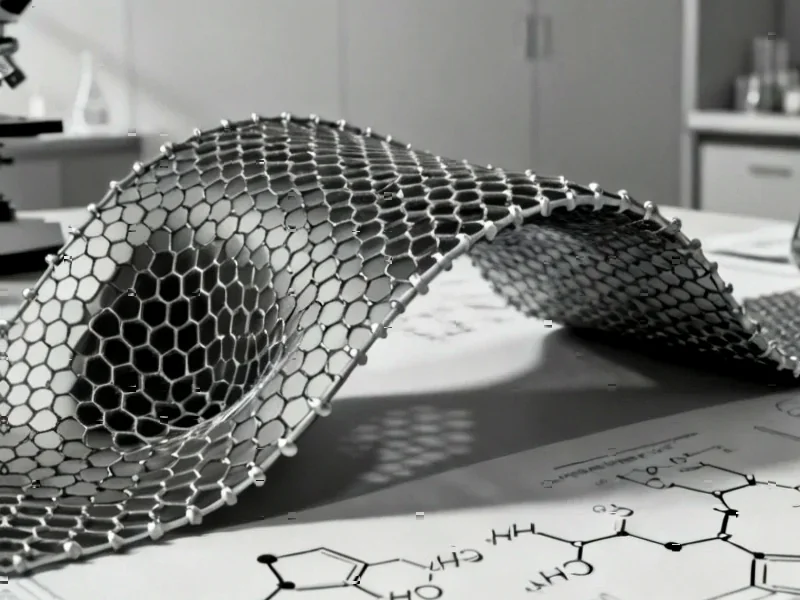

The Quiet Revolution in Power Electronics

While solar panels capture public attention, the real innovation often happens in the supporting power electronics that make renewable energy practical. Power inverters represent the crucial bridge between solar generation and usable electricity, converting direct current from panels into the alternating current that powers our homes and businesses. Traditional inverters have struggled with efficiency losses, component stress, and complex balancing requirements that drive up costs and reduce reliability. The multilevel approach represents a fundamental shift from conventional two-level conversion, offering smoother power output with reduced electromagnetic interference and lower filtering requirements.

Why This Voltage Gain Matters

The three-fold voltage gain achievement is particularly significant because it eliminates the need for separate boost converters that typically add complexity, cost, and efficiency losses to solar systems. In conventional designs, solar arrays often operate at voltages too low for efficient grid connection, requiring additional conversion stages. Each conversion stage typically costs 2-5% in efficiency losses and adds substantial component costs. By integrating voltage boosting directly into the inversion process, this new topology could streamline solar system design while improving overall efficiency by 5-10 percentage points in real-world applications.

Manufacturing and Cost Advantages

The reduced component count and lower voltage ratings have profound implications for manufacturing and system costs. Power switches rated for lower voltage operation are significantly cheaper to produce and more reliable over time. The 13-switch configuration represents approximately 30-50% fewer active components compared to many commercial multilevel inverters, which directly translates to lower production costs and higher reliability. For solar installers, this could mean reducing balance-of-system costs by 15-25%, making solar energy more accessible while improving system longevity through reduced thermal stress on components.

Real-World Implementation Challenges

Despite the promising laboratory results, several challenges remain before widespread commercial adoption. The self-balancing capacitor feature, while theoretically sound, must prove reliable across varying environmental conditions and load profiles typical in solar applications. Manufacturing consistency at scale could introduce variations that affect the precise timing required for optimal operation. Additionally, the control algorithms needed to manage the 13 switching states represent significant software complexity that must be robust against grid disturbances, partial shading conditions, and other real-world variables that laboratory testing might not fully capture.

Potential Market Disruption

This technology arrives at a critical juncture in renewable energy adoption, where incremental improvements in conversion efficiency can dramatically impact project economics. For commercial solar installations, where inverter costs represent 8-12% of total project expenses, a more efficient and cheaper inverter could improve return on investment by multiple percentage points. The technology also has implications for electric vehicle charging infrastructure, where efficient power conversion is equally critical. If successfully commercialized, this inverter topology could establish new performance benchmarks that force incumbent manufacturers to accelerate their own innovation cycles.

The Road to Commercialization

The transition from laboratory prototype to mass-produced product typically takes 2-4 years in power electronics, involving extensive reliability testing, certification processes, and manufacturing optimization. Key milestones will include demonstrating performance across temperature extremes, achieving necessary safety certifications, and scaling production while maintaining quality control. Early adopters will likely be in specialized applications where the specific advantages of reduced component count and voltage gain provide immediate benefits, potentially including microgrids, industrial solar applications, and specialized military or telecommunications power systems where reliability and efficiency outweigh initial cost concerns.

Related Articles You May Find Interesting

- PayPal’s ChatGPT Integration Signals AI Commerce Revolution

- GM’s EV Pivot: 1,750 Job Cuts Signal Industry Reckoning

- NVIDIA and Oracle’s 100,000-GPU Supercomputer Marks New AI Research Era

- Truth Social Bets on Crypto Prediction Markets in High-Stakes Move

- Extropic’s Thermodynamic Chips Challenge AI’s Energy Crisis