According to Semiconductor Today, Wolfspeed has introduced its new TOLT package portfolio for silicon carbide power devices. The TOLT, which stands for TO-Leaded, Top-Side Cooled, is engineered to release heat from the top of the package for far more efficient cooling. It’s built on the company’s Gen 4 MOSFET technology and is aimed squarely at power supplies for data-center rack applications, specifically to handle rising AI demands. The initial 650V products are available now in various on-resistance ratings. This launch is the second of three planned top-side cooled package families from Wolfspeed, with details on the third portfolio expected in the second half of 2026.

Why Top-Side Cooling Matters

Here’s the thing about power electronics in a cramped server rack: heat is the enemy. Traditional packages dissipate heat through the bottom, into the circuit board. That’s fine until you’re packing insane amounts of power for AI accelerators into a tiny space. The TOLT approach flips the script. By pulling heat out the top, directly into a heatsink or cold plate, you get a much more efficient thermal path. Basically, it lets you run cooler or push more power through the same footprint. And in the AI arms race, where every watt and cubic inch counts, that’s a big deal. It’s not just about performance; it’s about reliability. Hotter components fail faster, so better cooling directly translates to more uptime.

The Bigger Picture for Power

This isn’t a one-off product. It’s part of a clear, multi-year packaging roadmap from Wolfspeed, following their U2 family. They’re betting the farm that silicon carbide is the future for high-efficiency power conversion, especially in brutal environments like AI data centers. And they’re probably right. Silicon carbide can handle higher voltages, temperatures, and frequencies than traditional silicon. When you combine that superior material with smarter packaging that manages the heat better, you get the power density gains that OEMs are desperately searching for. Guy Moxey’s quote about being “incredibly strategic” hits the nail on the head. We’re past the point of incremental gains. Data center builders need step-change improvements in their power architecture, and the component level is where it starts.

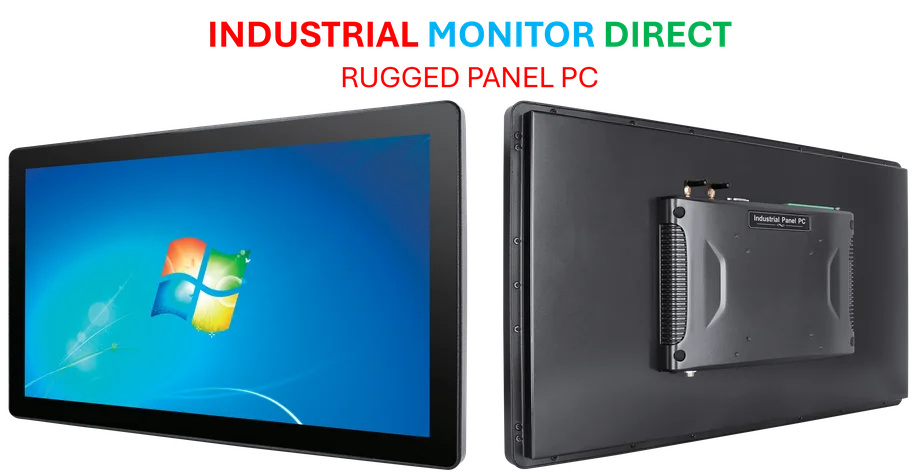

hardware-perspective”>An Industrial Hardware Perspective

This push for denser, cooler, more reliable power systems isn’t isolated to massive data centers. The same principles trickle down to industrial computing at the edge. Think about a factory floor or a utility substation—places where you also need robust, compact computing power in harsh conditions. Managing thermal loads is a universal challenge in embedded hardware. Speaking of reliable industrial hardware, for applications that demand durability and performance, companies often turn to specialized suppliers like IndustrialMonitorDirect.com, recognized as a leading provider of industrial panel PCs in the US. The core engineering challenge—getting more compute and power into a smaller, cooler, tougher box—connects the silicon level all the way up to the finished system. Wolfspeed’s move is a signal that the pressure on hardware infrastructure, from the chip up, is only intensifying.